-

Making the Brazilian ATR-72 Spin

by

[sc name=”post_comments” ][/sc]

Note: This story was corrected on August 10th at 10:23 am, thanks to the help of a sharp-eyed reader.

Making an ATR-72 Spin

I wasn’t in Brazil on Friday afternoon, but I saw the post on Twitter or X (or whatever you call it) showing a Brazil ATR-72, Voepass Airlines flight 2283, rotating in a spin as it plunged to the ground near Sao Paulo from its 17,000-foot cruising altitude. All 61 people aboard perished in the ensuing crash and fire. A timeline from FlightRadar 24 indicates that the fall only lasted about a minute, so the aircraft was clearly out of control. Industry research shows Loss of Control in Flight (LOCI) continues to be responsible for more fatalities worldwide than any other kind of aircraft accident.

The big question is why the crew lost control of this airplane. The ADS-B data from FlightRadar 24 does offer a couple of possible clues. The ATR’s speed declined during the descent rather than increased, which means the aircraft’s wing was probably stalled. The ATR’s airfoil had exceeded its critical angle of attack and lacked sufficient lift to remain airborne. Add to this the rotation observed, and the only answer is a spin.

Can a Large Airplane Spin?

The simple answer is yes. If you induce rotation to almost any aircraft while the wing is stalled, it can spin, even an aircraft as large as the ATR-72. By the way, the largest of the ATR models, the 600, weighs nearly 51,000 pounds.

Of course, investigators will ask why the ATR’s wing was stalled. It could have been related to a failed engine or ice on the wings or tailplane. (more…)

-

How the FAA Let Remote Tower Technology Slip Right Through Its Fingers

by

[sc name=”post_comments” ][/sc]

In June 2023, the FAA published a 167-page document outlining the agency’s desire to replace dozens of 40-year-old airport control towers with new environmentally friendly brick-and-mortar structures. These towers are, of course, where hundreds of air traffic controllers ply their trade … ensuring the aircraft within their local airspace are safely separated from each other during landing and takeoff.

The FAA’s report was part of President Biden’s Infrastructure Investment and Jobs Act enacted on November 15, 2021. That bill set aside a whopping $25 billion spread across five years to cover the cost of replacing those aging towers. The agency said it considered a number of alternatives about how to spend that $5 billion each year, rather than on brick and mortar buildings.

One alternative addressed only briefly before rejecting it was a relatively new concept called a Remote Tower, originally created by Saab in Europe in partnership with the Virginia-based VSATSLab Inc. The European technology giant has been successfully running Remote Towers in place of the traditional buildings in Europe for almost 10 years. One of Saab’s more well-known Remote Tower sites is at London City Airport. London also plans to create a virtual backup ATC facility at London Heathrow, the busiest airport in Europe.

A remote tower and its associated technology replace the traditional 60-70 foot glass domed control tower building you might see at your local airport, but it doesn’t eliminate any human air traffic controllers or their roles in keeping aircraft separated.

Max Trescott photo Inside a Remote Tower Operation

In place of a normal control tower building, the airport erects a small steel tower or even an 8-inch diameter pole perhaps 20-40 feet high, similar to a radio or cell phone tower. Dozens of high-definition cameras are attached to the new Remote Tower’s structure, each aimed at an arrival or departure path, as well as various ramps around the airport.

Using HD cameras, controllers can zoom in on any given point within the camera’s range, say an aircraft on final approach. The only way to accomplish that in a control tower today is if the controller picks up a pair of binoculars. The HD cameras also offer infrared capabilities to allow for better-than-human visuals, especially during bad weather or at night.

The next step in constructing a remote tower is locating the control room where the video feeds will terminate. Instead of the round glass room perched atop a standard control tower, imagine a semi-circular room located at ground level. Inside that room, the walls are lined with 14, 55-inch high-definition video screens hung next to each other with the wider portion of the screen running top to bottom.

After connecting the video feeds, the compression technology manages to consolidate 360 degrees of viewing area into a 220-degree spread across the video screens. That creates essentially the same view of the entire airport that a controller would normally see out the windows of the tower cab without the need to move their head more than 220 degrees. Another Remote Tower benefit is that each aircraft within visual range can be tagged with that aircraft’s tail number, just as it might if the controller were looking at a radar screen. (more…)

-

Could Knowledge of Undisclosed MCAS Have Saved Lion Air 610?

by

[sc name=”post_comments” ][/sc]

Could Knowledge of Undisclosed MCAS Have Saved Lion Air 610?

Could Knowledge of Undisclosed MCAS Have Saved Lion Air 610?By Rob Mark

Having spent more than a few decades in the cockpit, I thought even I’d reached that plateau where I could claim I’d just about seen it all … until this week’s admission by Boeing of an – until now, unknown – automated AoA related stall-prevention system called MCAS that, even when the aircraft is being hand flown, could yank the control column away from an unsuspecting pilot.

Details are of course still sketchy, but I’m dumbfounded that anyone at Boeing could be so certain of a computerized system aboard the 737 Max 8, that they saw no need to mention its existence to operators or pilots.

_____________________________________

From Flying eNews, November 15, 2018 …

In what some pilots are calling an inconceivable moment in flight operations and training, Boeing recently admitted the existence of the maneuvering characteristics augmentation system (MCAS), an angle of attack related stall prevention system that was unknown to operators of the Boeing 737 Max 8 aircraft, like the one flown last week by a Lion Air crew when it departed Jakarta Indonesia. The Lion Air crew experienced an unexpected nose pitch down shortly after takeoff as the aircraft was passing through 5,000 feet. Unable to recover from the event, all 189 people aboard perished in the crash that followed.

While it’s too early to draw any solid conclusions, there appears to be a circumstantial link between the, until now unknown MCAS and the angle of attack error messages reported early on following the Lion Air accident. The FAA last week issued an emergency airworthiness directive against the 737 Max 8 that said, “erroneously high single angle of attack (AOA) sensor input could result in “repeated nose-down trim commands of the horizontal stabilizer,’ which could be from the MCAS,” according to the Aviation Safety Network.

Operators of the 737 Max aircraft wasted no time making clear their feelings about Boeing’s apparent oversight in the release of MCAS information. In a message yesterday, ASN says the Allied Pilots Association (APA), which represents American Airlines Group Inc. pilots, alerted its members … to the MCAS saying “it applies nose down stabilizer in specific conditions when the aircraft nears a stall,” the first time many pilots were made aware of the system’s existence.

The APA said the logic behind MCAS was not mentioned in training or in any other manuals or materials. Safety Committee Chairman Capt. Michaelis stated, “It’s pretty asinine for them [Boeing] to put a system on an airplane and not tell the pilots who are operating the airplane, especially when it deals with flight controls,” according to the ASN.

A Boeing message quoted by the APA said, “the MCAS (Maneuvering Characteristics Augmentation System) is implemented on the 737 MAX to enhance pitch characteristics with flaps UP and at elevated angles of attack. The MCAS function commands nose down stabilizer to enhance pitch characteristics during steep turns with elevated load factors and during flaps up flight at airspeeds approaching stall. MCAS is activated without pilot input and only operates in manual, flaps up flight. The system is designed to allow the flight crew to use column trim switch or stabilizer aisle stand cutout switches to override MCAS input. The function is commanded by the Flight Control computer using input data from sensors and other airplane systems.

A January 2018 report of the new Boeing’s created by the Brazilian ANAC briefly mentions the MCAS, but offers no specific guidelines on its operation. Whether the Lion Air 610 crew had any knowledge of the MCAS’s existence prior to their October 29 takeoff is unknown. Sources said Boeing risk assessment team felt the chances of the MCAS going off in flight were so remote, they felt an explanation of the system was unnecessary

Boeing told Flying through a prepared statement in part, “We are taking every measure to fully understand all aspects of this incident, working closely with the investigating team and all regulatory authorities involved … Safety remains our top priority and is a core value for everyone at Boeing. While we can’t discuss specifics of an on-going investigation, we have provided two updates for our operators around the world that re-emphasize existing procedures for these situations.”

Capt. John Weaks, president of Southwest Airlines Pilots Union (SWAPA) quoted in the Wall Street Journal said, “We’re pissed that Boeing didn’t tell the companies and the pilots didn’t get notice obviously, as well. But what we need now is to make sure there is nothing else Boeing has not told the companies or the pilots.”

Reprinted by permission of Flying magazine

Rob Mark is also Publisher of Jetwhine.com

-

Enstrom Artisans Build Helicopters with Personality

by

[sc name=”post_comments” ][/sc]

Waggism, playful lightheartedness, is the last thing one would expect to see at a facility dedicated to the deadly serious business of building FAA-certificated aircraft. But then I met Sally, her name printed on an aluminum placard in red Sharpie on the wide end of a fixture used to build tail booms at Enstrom Helicopter in Menominee, Michigan.

Waggism, playful lightheartedness, is the last thing one would expect to see at a facility dedicated to the deadly serious business of building FAA-certificated aircraft. But then I met Sally, her name printed on an aluminum placard in red Sharpie on the wide end of a fixture used to build tail booms at Enstrom Helicopter in Menominee, Michigan.Curious, I asked Dan Nelson about it. Was this the work of some unknown wag, an aeronautical version of Kilroy was Here?. Taking a moment, he carefully put down his Cleco pliers and explained that Sally was the name of the piston-powered helicopter just conceived at the factory. “We started naming them some months ago,” said Dan, a sheet metal master who introduces newcomers to the craft and mentors their mastery of it.

“There was a picture on Facebook of a fleet of our helicopters on the ramp for delivery, and someone said we should start naming them.” The piston-powered F-28F and 280FX get girl names, and boy names identify the turbine-powered 480B. “It’s just for fun,” he said with the unapologetic tone of a father talking about his children.

Perhaps naming these gestational helicopters isn’t so waggish. Expectant parents often name the nugget of their baby to give it an identity, to make it more than a bump, to connect on a more intimate, personal level. The only real difference is that the helicopter’s names stay in the womb. Like all parents, the customers who take the newborn Enstrom home have the naming rights.

The riveted monocoque is just one appendage connected to the welded steel-tube pylon that is the Enstrom’s thorax. Working in robust rotating fixtures that look like complex gyms—yellow for pistons an green for turbines—it takes Enstrom’s state-certified welders about three weeks to weld a pylon, said Dennis Martin, Enstrom’s director of sales and marketing.

The riveted monocoque is just one appendage connected to the welded steel-tube pylon that is the Enstrom’s thorax. Working in robust rotating fixtures that look like complex gyms—yellow for pistons an green for turbines—it takes Enstrom’s state-certified welders about three weeks to weld a pylon, said Dennis Martin, Enstrom’s director of sales and marketing.The welders work with pre-notched tubing, he explained, and the three weeks includes their final fitting, sand blasting, multiple inspections, and a light skim coat of primer that makes imperfections stand out. “We like steel because it’s easier to inspect and repair,” said Martin. “But the main reason is that steel will absorb a great deal of energy.

“If you look at the S-N Curve [a plot of the magnitude of an alternating stress versus the number of cycles to failure for a given material], once it fails, steel continues to absorb energy, which means it is not transferred to the occupants. It doesn’t have a sharp drop off; once aluminum or composites fail, it’s done—it doesn’t absorb any more energy,” said Martin.

“If you look at the S-N Curve [a plot of the magnitude of an alternating stress versus the number of cycles to failure for a given material], once it fails, steel continues to absorb energy, which means it is not transferred to the occupants. It doesn’t have a sharp drop off; once aluminum or composites fail, it’s done—it doesn’t absorb any more energy,” said Martin.Just around the corner, in the composite shop, Tom Retlick is laying up the some seats that combine different layers of foam and glass that work in concert to provide lightweight rigidity, comfort, and a degree of energy absorption. Just celebrating 23 years at Enstrom, he’s surrounded by his work, artistry embodied by the split molds for each model’s cabin and attendant fairings.

The heart of Enstrom’s birthplace is the climate-controlled cube that is the quality department. “It’s such a crazy juxtaposition,” said Roger Hardy after setting a raw casting of the idler pulley for the piston power train in the Conner CNC measuring machine. Just outside those doors there are artisans bucking rivets, welding steel, and laying up and cooking composites “all under one roof with CNC measuring and milling machines.”

“It takes some time to program the machine” to measure dozens of specific points on a part, said Hardy, who starts the effort with the part’s drawing. “But it goes to the exact same point on every part with a consistency that gives a true measure of each part.” He’ll see this part again, after it takes its turn in a CNC mill to become a finished idler pulley.

“It takes some time to program the machine” to measure dozens of specific points on a part, said Hardy, who starts the effort with the part’s drawing. “But it goes to the exact same point on every part with a consistency that gives a true measure of each part.” He’ll see this part again, after it takes its turn in a CNC mill to become a finished idler pulley.After making sure my curiosity had satisfied its current queries, he thanked me, and returned to work, as had all of the artisans I’d talked to this day. Each of them was knowledgeable and friendly, and prompted by my questions, they eagerly shared their knowledge in terms neither patronizing nor overtly technical. As a group, their personality was one of proud parenthood. — Scott Spangler, Editor

-

FAA Bill Creates National Airmail Museum

by

[sc name=”post_comments” ][/sc]

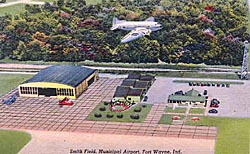

Title V of the FAA Reauthorization Act of 2018 is an accumulation of Congressional mandates that don’t qualify for its other titles, like Title IV—Air Service Improvements, and Title III—Safety. This item caught my eye. It’s short, so here’s a copy and paste of the whole thing.

Title V of the FAA Reauthorization Act of 2018 is an accumulation of Congressional mandates that don’t qualify for its other titles, like Title IV—Air Service Improvements, and Title III—Safety. This item caught my eye. It’s short, so here’s a copy and paste of the whole thing.SEC. 526. NATIONAL AIRMAIL MUSEUM.

(a) FINDINGS.—Congress finds that—

(1) in 1930, commercial airmail carriers began operations at Smith Field in Fort Wayne, Indiana;

(2) the United States lacks a national museum dedicated to airmail; and

(3) the airmail hangar at Smith Field in Fort Wayne, Indiana—

(A) will educate the public on the role of airmail in aviation history; and

(B) honor the role of the hangar in the history of the Nation’s airmail service.

(b) DESIGNATION.—

(1) IN GENERAL.—The airmail museum located at the Smith Field in Fort Wayne, Indiana, is designated as the “”National Airmail Museum”.

(2) EFFECT OF DESIGNATION.—The national museum designated by this section is not a unit of the National Park System and the designation of the National Airmail Museum shall not require or permit Federal funds to be expended for any purpose related to that national memorial.Asking Google about it let me to the National Airmail Museum’s website. Now fundraising, the museum will not only educate visitors about the airmail era, it will describe Fort Wayne’s role in the system’s development. Housed in Hangar 2 at Smith Field Airport, the museum will feature interactive and hands-on exhibits that will give visitors a deeper understanding and appreciation of the trials and tribulations of the pilots and those who supported them. It will also be home to EAA Chapter 2, a gift shop, and a uniquely themed dining experience.

Hangar 2 is itself a bit of history. To quote the website: Built in the 1920s, “Hangar 2 features three large Truscon Steel Company Doors, a highlight unique to Smith Field in the U.S. at the time they were built. The Carousel Hangar, although outside the period of significance defined for Smith Field, is the only example of Clark W. Smith’s patented design ever built. The hangar is characterized by an innovative rotating carousel door. Smith Field’s tie-down area recalls the era before World War II when hangars were used for maintenance rather than storage, and the aircraft had to be tied down to spiral-shaped stakes in the ground.”

Unlike most airports in operation today, Smith Field was not built for or during World War II. It grew then, but Fort Wayne inspected the site in 1919, pilots started learning to fly there in 1923, and it was established at the Baer Municipal Airport in 1925, named for Paul Baer, America’s first ace in World War I. During World War II, when the Army Air Forces appropriated Baer’s name for its airfield south of town, Fort Wayne renamed the airport for its airmail pioneer, Art Smith.

Unlike most airports in operation today, Smith Field was not built for or during World War II. It grew then, but Fort Wayne inspected the site in 1919, pilots started learning to fly there in 1923, and it was established at the Baer Municipal Airport in 1925, named for Paul Baer, America’s first ace in World War I. During World War II, when the Army Air Forces appropriated Baer’s name for its airfield south of town, Fort Wayne renamed the airport for its airmail pioneer, Art Smith. Born on February 27, 1890 in Fort Wayne, he died on February 12, 1926, the second overnight mail service pilot to die on duty. His parents mortgaged their home in 1910 so Art could build his first plane. Teaching himself to fly, he crashed on its first flight. Learning by trial and error, he became a stunt pilot, taking over at the official Panama-Pacific International Exhibition’s stunt flyer when Lincoln Beachey did not survive a crash in San Francisco Bay. During World War I he was an Army test pilot and instructor, stationed at Virginia’s Langley Field McCook Field in Dayton, Ohio. He joined the Post Office after the war and flew overnight mail between New York City and Chicago, and died on his route near Montpelier, Ohio.

Born on February 27, 1890 in Fort Wayne, he died on February 12, 1926, the second overnight mail service pilot to die on duty. His parents mortgaged their home in 1910 so Art could build his first plane. Teaching himself to fly, he crashed on its first flight. Learning by trial and error, he became a stunt pilot, taking over at the official Panama-Pacific International Exhibition’s stunt flyer when Lincoln Beachey did not survive a crash in San Francisco Bay. During World War I he was an Army test pilot and instructor, stationed at Virginia’s Langley Field McCook Field in Dayton, Ohio. He joined the Post Office after the war and flew overnight mail between New York City and Chicago, and died on his route near Montpelier, Ohio.Aviation as we know it today would not exist without the people who created the airmail system and made it work. That they deserve national recognition should be beyond question. Equally important, aviators today should support the National Airmail Museum because in recognizing the dedication and sacrifices of pioneers like Art Smith, we can inspire these traits among those who are building aviation’s future. Scott Spangler, Editor.